Looking to add a low rise car lift to your home garage? This article is for you!

As you’ll read below, we discuss the three most common types of low rise vehicle lifts (aka low clearance vehicle lifts) in terms of options, advantages, and disadvantages. Here’s what you need to know.

First, A Note About Hydraulics

Many of the car lifts designed for the home market are powered by hydraulics, especially the models with lots of great marketing. And this makes sense – what’s more satisfying than pressing a button and watching a car go up or down?

Here’s the thing: Good hydraulic systems are expensive. The commercial lifts we offer use top grade motors, pumps, cylinders, lines, fittings, and seals. That’s because, in a commercial environment, a lift will be used several times a day. They need top-notch hydraulics to have commercial value.

“Enthusiast” grade vehicle lifts, on the other hand, do not need top-notch hydraulics. Most consumers will use their lift a few times a week (if that), and as a result, many of the enthusiast lifts use cheap imported hydraulic components.

Here are some telltale signs of a cheaply-built hydraulic system:

- Rubber lines instead of stainless steel

- An undersized hydraulic cylinder without any sort of warranty

- Fittings that leak

- Motors that have warnings about overheating, even during normal use

- Low weight ratings that just barely lift the average car (the average car in the US weighs more than 3,500lbs – if you see a lift with a rating that’s 3,500 lbs or less, you’ve been warned)

Remember: A cheap hydraulic system with an undersized hydraulic cylinder or an underpowered lift motor will work great for 3-5 years, depending on use. But eventually, the cheap parts will shine through.

1. Low Clearance or “Portable” 2-Post Lifts

Probably the most popular lift in the auto service industry, the 2-post lift works great for nearly every type of service or repair activity. However, commercial grade 2-post lifts require quite a bit of room to operate (both vertically and horizontally). You need a ceiling that’s over 12 feet high to accommodate a commercial 2-post lift, and you’ll need a wider than standard garage space (or a 2 car garage you’re willing to use as a 1 car garage).

There’s such a thing as a ‘portable’ 2-post lift, and while we’ve seen these advertised, we haven’t seen any well-known lift manufacturers offering them. There are a few issues with a small 2-post lifts that we’ve seen on the market:

- Concrete anchors should be permanent. In order to install a quality 2-post lift, you need a concrete pad that’s 4-6″ thick, 3,000 PSI concrete, and solid anchors drilled into the concrete. Portable 2-post lifts are supposed to be capable of quick attachment and removal, but this can cause anchors to loosen. Over time, loose anchors can lead to catastrophic failure.

- Lack of repair parts. Like all inexpensive hydraulic lifts, it’s hard to buy replacement parts from the manufacturer. Many of the companies selling inexpensive 2-post lifts do not offer replacement parts whatsoever.

While there may be an excellent 2-post lift on the market that works with a low ceiling height and costs half as much as a commercial 2-post lift, we haven’t seen one. If you want a 2-post lift, our advice is to buy a commercial grade 2-post lift that’s ALI certified and have it installed by a trained technician to prevent injury and/or vehicle damage. If you can’t make a commercial grade unit work because of space requirements, we say skip it.

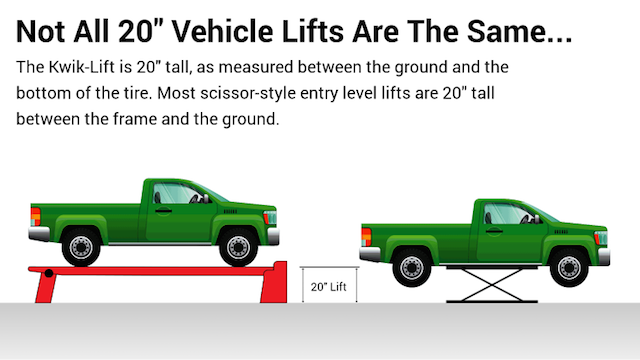

2. Entry-Level Scissor Style Lifts

Scissor style vehicle lifts have a few common traits:

- They lift a vehicle by the frame rather than at the designated lift points or the wheels. This is unusual, as 2-post lifts work at the designated jack points, and 4-post lifts (or the Kwik-Lift) lift at the wheels. The scissor style lifts usually have blocks that distribute the weight across a frame pinch point, but that’s definitely not recommended.

- They sit between the vehicle’s wheels. This can be a problem for long wheelbase vehicles…it’s not at all unheard of for a long wheelbase vehicle to tip forward or backward when up on a scissor style lift (especially during a transmission or rear-end removal, when the center of gravity can shift front or rearwards).

- Scissor style lifts are usually 3-4″ tall. This height means they aren’t compatible with low ground clearance vehicles – you have to get the 3-4″ tall lift under the car. Also, a lot of these lifts can’t lift from their completely folded position…then need an inch or two of rise “get going” in many cases.

- Scissor style lifts usually offer minimal lift. Because scissor style lifts work against the frame rather than the tires, a good portion of their “lift” is used to get up to the frame…if you have a vehicle with 7″ of ground clearance, for example, than 7″ of your lift’s 18″ rise height goes to reaching the frame. Sometimes, blocks can be used to help with this problem, but the blocks aren’t as steady as many people would like (there are reports of scissor lifts that use blocks getting “wobbly” at full rise).

- Inexpensive hydraulic systems. Almost all scissor style lifts use low cost hydraulics to operate the lift mechanism, which has the downsides we covered earlier.

While every lift has some utility, we’d argue that most of the scissor style lifts on the market don’t offer as much as the Kwik-Lift. Obviously, we’re biased here, but in our view, a lift that doesn’t work with every car – and that doesn’t lift a car at a designated lift point – isn’t worth having. The fact that many of these lifts have cheap hydraulic systems is just another great reason not to own one.

3. The Kwik-Lift

Here’s our best attempt to give you the Kwik-Lift’s pros and cons, starting with the pros.

- The Kwik-Lift lifts a car on its wheels. When you lift a car the right way, there’s no need to worry about front/rear weight distribution. You can get under a Kwik-Lift without worrying about your vehicle tipping forward or backward during an axle swap (for example).

- The Kwik-Lift offers a good amount of lift. Depending on your vehicle’s ground clearance, you’ll have at least 20″ of room to work with, and typically 24-28″. This is just about the ideal distance for use with a creeper – it also gives you enough space to drop a transmission, which can be 16-18″ tall on some vehicles.

- The Kwik-Lift works with every car. Because the Kwik-Lift is basically just a ramp with a clever lifting mechanism, you can get nearly any car up onto the lift (regardless of ground clearance). Additionally, the width and length of the lift is adjustable.

- The Kwik-Lift doesn’t rely on cheap hydraulics. Hydraulic systems are impressive – and we’re sure that a lot of people are drawn to cool videos showing hydraulic lifts going up and down – but cheap hydraulics don’t last. If you spend $1500 on an entry-level hydraulic lift and have to cough up another $500 to refurbish the lift’s hydraulics in a few years, what’s the point?

- The Kwik-Lift is truly portable. You can break down the Kwik-Lift into its component pieces and haul it in a pickup truck. Or, you can completely lower it and park right on top of it.

- The Kwik-Lift is simple to use. By design, the Kwik-Lift can be setup and used by anyone. There’s no need for special training, anchors, or tools.

The Kwik-Lift’s cons:

- It’s not cheap. The Kwik-Lift is solid steel and made in the USA. It’s wider than it needs to be to ensure maximum stability, and it’s heavy as a result. While we could probably reduce the price using “aircraft grade” aluminum (whatever that means), building our lift overseas, and going with a narrower setup that was a little wobbly, we’re not going to do any of these things.

- You need to do your own lifting. There are no buttons to impress the neighbors. If you want your vehicle up in the air, you need a good quality floor jack and some elbow grease.

- You’ll want a center-lift bridge or a regular jack to remove wheels. If you’re using the Kwik-Lift to do brake work (for example) you’ll want to either support the axle with a jack on the centerlift bridge, or you’ll want to put a jack between the lift rail and the designated jack point.

Finally, we’d like to point out that the Kwik-Lift has awesome resale value. Unlike a used hydraulic lift, there’s no risk of buying a “bad” Kwik-Lift. As long as the Kwik-Lift doesn’t have obvious damage, it’s working. If you occasionally lubricate your Kwik-Lift – and remember to paint any scratches to prevent rust – your Kwik-Lift should last a lifetime.

Previous Article

What You Can Do With a Kwik-Lift That You Can't Do With an Entry-Level Hydraulic Lift

2 Comments

I would like to know if you have any pictures of the ramps in the flat position? I would also like to know what it takes to set up, and lay down flat. Can one person do this?

Hi Jeffrey,

You can see images on our Facebook page. Here’s one: Facebook LinkAnd check out our videos for setup: https://www.kwik-lift.com/how-tos/

Thanks for your comment!